According to Bloomberg, in April 2022, the production level of US manufacturing businesses plummeted to its lowest from May 2020. Manufacturers are plagued by record-long 100-day lead times for delivering production materials. Labor shortages also persist. All of these are related to issues caused by the Covid-19 pandemic, which is still rampant worldwide. Companies can make production faster by using machine vision to offset these problems.

The demand for products from manufacturers in the US remains strong, and orders’ backlog continues to increase. That shows significant potential for revenues if only these backlogs can be met.

This article will explore how machine vision can help manufacturers speed up production to meet order backlogs. Even more, using machine vision can help manufacturers ensure high quality and lower costs, gaining customers’ approval and boosting revenue.

What is Machine Vision and How Is It Used in Manufacturing?

Machine vision is a technology that allows machines to “see.” It uses a combination of cameras, lenses, software, and lighting to capture images that can be analyzed by a computer. This data can be used to make decisions or take action.

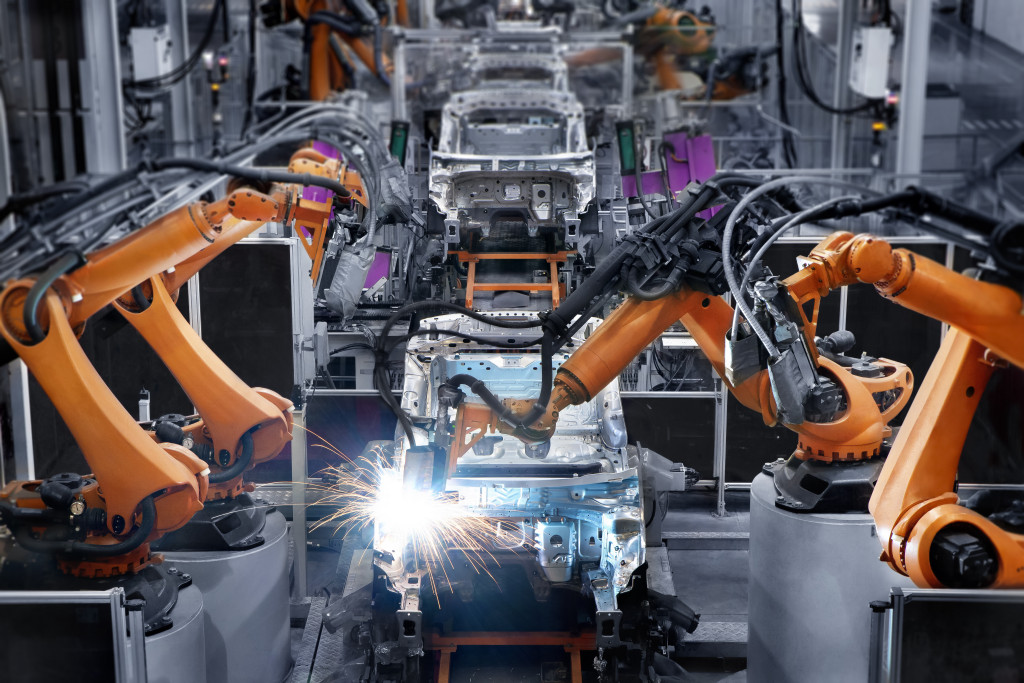

In manufacturing, machine vision is used for quality control. Manufacturers can identify defects and avoid shipping faulty products by inspecting products at high speeds.

For instance, The iVu and iVu Color Image Sensors from Sensors Incorporated can monitor the color variation in parts as well as type, shape, size, orientation, and location. This is several times more accurate and faster than human monitoring. Machine vision can also be used for assembly, robotic guidance, and barcode reading.

How Does Machine Vision Boost Revenue?

There are several ways that machine vision can help manufacturers boost their revenue:

Increased Production Speed

In manual inspection, human error and slow human reflexes cause delays. This is costly. By automating quality control with machine vision, manufacturers can avoid these delays.

The use of machine vision in manufacturing assembly lines can also help to speed up production. For example, machine vision can guide robots on the assembly line. This helps to improve accuracy and increase productivity.

Also, shortages in labor can affect production speed as there will be fewer people available to assign to manual inspection and assembly. Automating quality control and assembly with machine vision can help to increase production speed and improve efficiencies.

Improved Product Quality

Having to rework products causes further production delays. Having to scrap faulty products increases waste. Both are costly.

In addition to increased production speed, automating quality control and the assembly line with machine vision can improve product quality. It can identify defects through quality control early in the manufacturing process, enabling immediate adjustment. It can also ensure that the assembly of products is consistently correct. Manufacturers can then avoid the cost and time associated with reworking or scrapping products.

Reduced Costs

When manufacturers ship products with defects, they incur costs from returns, replacements, and repairs. They may have to refund buyers or pay penalties on their contracts. In some cases, they may even lose customers. Furthermore, shipping defective products affect the manufacturer’s reputation, lowering future revenue.

By ensuring precise quality control and assembly, machine vision avoids the cost of shipping defective products. It also saves resources by helping reduce material waste throughout the production process.

In addition, by automating quality control inspection and assembly, manufacturers can avoid the cost of hiring more inspectors and assembly line workers. This is also helpful when there are labor shortages.

Improved Customer Satisfaction

Customers have been waiting for delayed orders, and companies that can deliver will rise above the competition. Building a reputation of delivering orders on time will result in more customers and larger orders.

Also, by reducing the number of defective products, manufacturers can reduce the number of returns. Even better, ensuring the delivery of only high-quality products will cement a manufacturer’s reputation for excellence, leading to satisfied customers and repeat business.

Manufacturers can earn customer loyalty by using machine vision to improve production speed and product quality. This is because customers are more likely to stay with a supplier whose products are delivered on time and meet their quality expectations.

Use Machine Business Vision to Achieve a Competitive Edge

In today’s competitive marketplace, manufacturers need to do everything to improve efficiency and product quality and reduce costs. Machine vision can play a crucial role in achieving these goals. By automating quality control inspection and assembly tasks, manufacturers can speed up production, ensure that products meet the highest standards, and lower costs.

This can lead to increased customer satisfaction, more customers, and customer loyalty. With machine vision, manufacturers can have the best of both worlds: a high-quality product delivered quickly and efficiently at the lowest cost possible. Using machine vision in your manufacturing process is the key to boosting revenue and giving your company a competitive edge.